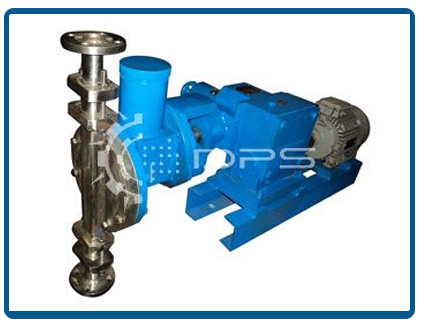

Our Products - Diaphragm Pumps

Diaphragm Pumps are recommended for hazardous, Toxic and Poisonous liquids, where leakage is not at all permitted. Diaphragm pumps have hydraulically actuated diaphragm and a back pressure valve. The main function of back pressure valve is to balance the hydraulic oil in the chamber. The reciprocating plunger transmit displacement through hydraulic oil to the diaphragm, the oscillation of diaphragm produces pumping action on process fluid with help of Non-Return Valve in built at both ends. The diaphragm acts as a perfect seal between the hydraulic oil and the liquid being pumped. Diaphragm pump can be provided with single or double diaphragm; usually Teflon acts as a diaphragm. The back pressure valve which is in the hydraulic oil tank ensures pumping accuracies for long period. The pressure drop in hydraulic chamber due to oil leakage is automatically compensated by opening back pressure valve. Besides back pressure valve acts as safe guard from damages if discharge pressure exceeds pump rated pressure.

Diaphragm Pumps are recommended for hazardous, Toxic and Poisonous liquids, where leakage is not at all permitted. Diaphragm pumps have hydraulically actuated diaphragm and a back pressure valve. The main function of back pressure valve is to balance the hydraulic oil in the chamber. The reciprocating plunger transmit displacement through hydraulic oil to the diaphragm, the oscillation of diaphragm produces pumping action on process fluid with help of Non-Return Valve in built at both ends. The diaphragm acts as a perfect seal between the hydraulic oil and the liquid being pumped. Diaphragm pump can be provided with single or double diaphragm; usually Teflon acts as a diaphragm. The back pressure valve which is in the hydraulic oil tank ensures pumping accuracies for long period. The pressure drop in hydraulic chamber due to oil leakage is automatically compensated by opening back pressure valve. Besides back pressure valve acts as safe guard from damages if discharge pressure exceeds pump rated pressure.

Range of Capacity - ‘DENCIL’ Brand diaphragm Pump is available for 0.5 Ltrs to 12,000 Litres per hour and pressure up to 100 Kg/cm2 in various model to suits client application.

DENCIL offers :

- Hydraulic Operated Diaphragm Pumps

- Mechanical Operated Diaphragm Pump

Design feature/benefits of diaphragm pumps:

- For diaphragm pump discharge pressures to 20 kg/cm2 (300psi)

- Pneumatic and electric stroke length control available, automatic capacity control in response to standard 4-20MA process signal.

- Explosion proof motors available suitable for use in hazardous atmospheres.

- Lowflowrates accurate, reliable chemical feed.

- Accuracy ± 2%.

Design Facilities

- Standard pump models selection considering Viscosity, vapor pressure, Specific gravity.

- Piping layout (Acceleration losses & NPSHR)

- Computer aided design (CAD) for general Assembly.

Tests performed on each pump

- Flow rate

- Power consumption

- Pressure test

Applications :

- Basic intermediate and finished products, petrochemical and pharmaceuticals industries.

- Machine building, mining, metal processing, filling and extraction technology

- Crude oil, natural gas, coal, nuclear power.

- Raw materials, liquid products, dairy products, pasta, baked goods, sweet tobacco

- Paper, cellulose, textiles, leather, synthetic, fibers or material, building materials, cleaners and detergent, film, tapes

- Water treatment, air cleaning, disposal techniques

- Dialysis, stored blood.

Diaphragm Pumps are recommended for hazardous, Toxic and Poisonous liquids, where leakage is not at all permitted. Diaphragm pumps have hydraulically actuated diaphragm and a back pressure valve. The main function of back pressure valve is to balance the hydraulic oil in the chamber. The reciprocating plunger transmit displacement through hydraulic oil to the diaphragm, the oscillation of diaphragm produces pumping action on process fluid with help of Non-Return Valve in built at both ends. The diaphragm acts as a perfect seal between the hydraulic oil and the liquid being pumped. Diaphragm pump can be provided with single or double diaphragm; usually Teflon acts as a diaphragm. The back pressure valve which is in the hydraulic oil tank ensures pumping accuracies for long period. The pressure drop in hydraulic chamber due to oil leakage is automatically compensated by opening back pressure valve. Besides back pressure valve acts as safe guard from damages if discharge pressure exceeds pump rated pressure.

Diaphragm Pumps are recommended for hazardous, Toxic and Poisonous liquids, where leakage is not at all permitted. Diaphragm pumps have hydraulically actuated diaphragm and a back pressure valve. The main function of back pressure valve is to balance the hydraulic oil in the chamber. The reciprocating plunger transmit displacement through hydraulic oil to the diaphragm, the oscillation of diaphragm produces pumping action on process fluid with help of Non-Return Valve in built at both ends. The diaphragm acts as a perfect seal between the hydraulic oil and the liquid being pumped. Diaphragm pump can be provided with single or double diaphragm; usually Teflon acts as a diaphragm. The back pressure valve which is in the hydraulic oil tank ensures pumping accuracies for long period. The pressure drop in hydraulic chamber due to oil leakage is automatically compensated by opening back pressure valve. Besides back pressure valve acts as safe guard from damages if discharge pressure exceeds pump rated pressure.

Range of Capacity - ‘DENCIL’ Brand Hydraulic diaphragm Pump is available for 0.5 Ltrs to 12,000 Litres per hour and pressure up to 100 Kg/cm2 in various model to suits client application.

Dencil Offers : SIMPLEX HYDRAULIC DIAPHRAGM PUMPS

| TECHNICAL SPECIFICATION | |

|---|---|

| Capacity | 10000LPH |

| Pressure | Upto 100 Bar |

| Material of Construction | As Per your requirements which include PP / PVC / PVDF / TEFLON / SS 304 / SS 316 Alloy 20, HASTEALLOY, TITANIUM etc. |

We offer technically advanced Mechanical Operated Diaphragm Pumps which are widely in demand in market because of low maintenance requirement. Providing absolute solution for batching operation, our pumps are based on simple and robust crank mechanism or spring return mechanical diaphragm pump. Being developed for handling corrosive liquid and those containing suspension of abrasive solids the pumps use mechanically-actuated diaphragm to combine the characteristics of a plunger pump (linear flow rate) with the sealing advantages of a diaphragm pump.

We offer technically advanced Mechanical Operated Diaphragm Pumps which are widely in demand in market because of low maintenance requirement. Providing absolute solution for batching operation, our pumps are based on simple and robust crank mechanism or spring return mechanical diaphragm pump. Being developed for handling corrosive liquid and those containing suspension of abrasive solids the pumps use mechanically-actuated diaphragm to combine the characteristics of a plunger pump (linear flow rate) with the sealing advantages of a diaphragm pump.

Our pumps are separated in two sections which are separated by a diaphragm. Piston or plunger separates operates in a cylinder of one section for displacing the non-corrosive fluid which is transmitted by a flexible diaphragm to the liquids to be pumped. Especially designed valves are the only moving part in the pump that are in contact with the liquid to be pumped and efficiently handles the material. Sometimes, the movement of the diaphragm may be air actuated or the movement of diaphragm is produced by direct mechanical action.

Dencil Offers :

Simplex Mechanical Operated Diaphragm Pumps

Duplex Mechanical Operated Diaphragm Pumps

Multiplex Mechanical Operated Diaphragm Pumps

| TECHNICAL SPECIFICATION | |

|---|---|

| Capacity | 1500 LPH |

| Pressure | Upto 5 Bar |

| Material of Construction | As Per Your Requirements Which Include PP/PVC/ PVDF / TEFLON/ SS 304 / SS 316 ALLOY 20, HASTE ALLOY, TITANIUM ETC |